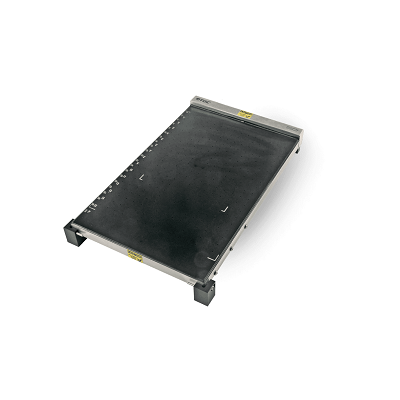

Heated perforated vacuum table to be used to create smooth and consistent thin films of paint, lacquers and other materials on sample specimen such as opacity test charts, sample panels, foils or other flat substrates.

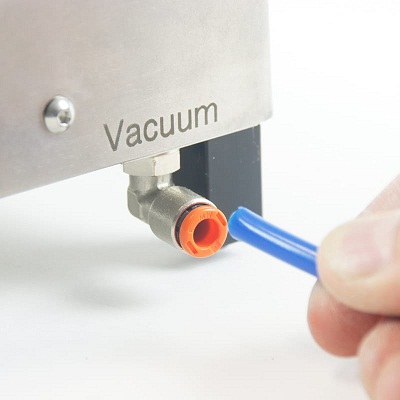

The vacuum table is made of hard aluminium and anodized in hard-coat flat black to provide a durable and inert surface with an absolute flatness. The surface of the vacuum table is perforated with a grid of small holes which hold the test specimen in position for proper drawdown when attached to a vacuum pump or line (not included)

The vacuum table has a built-in heating mat which allows the temperature of the table to be elevated up to +100°C above ambient temperature. The powerful heating device guarantees an even distribution of the temperature over the entire vacuum plate. Temperature is set and controlled through a digital temperature controller.

Unlike with the TQC automatic film applicator the films are to be applied manually using a variety of applicators such as block-applicators, baker-applicators, bar-coaters and wire wound rods, Bird-applicator, Quadruplex applicators, Biddle duplex applicators, System Wasag, Casting knife and Micrometric film applicators.

APPLICATIONS

• Apply even and consistent films op paint and coatings on test charts to evaluate opacity, hiding power, penetration resistance, spreading rate

• Produce consistent and reproducible test charts for colour comparison, gloss and reflectance testing and other appearance parameters.

• Apply adhesives, glue and hot melt on test specimen to evaluate bonding strength at different thicknesses and different temperatures.

• Apply slurries on metal foils for research after new thin film technologies in the battery production industry

• Produce reproducible test charts and specimen for scrub -, abrasion- and washability tests.