Analysing foam parameters, Controlling surfactant effects

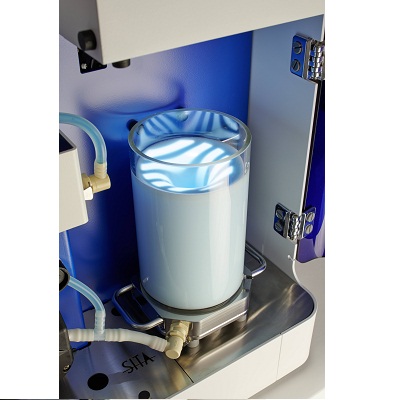

The long-time successful SITA foam tester R-2000 was the first fully automated foam tester with a reproducible foam generation.More than 15 years of experience in foam testing led to a next generation testing device, the new SITA FoamTester.

|

• Innovative optical measuring method • Fully automated foam analysis • Precise reproducible foaming • Measuring foam and liquid volume • Analysing foam structure • Recording drainage |

Product Description

The SITA FoamTester analyses the characteristics of surfactant-containing liquids easy, fast and precise with automated measuring sequences. The measuring device uses innovative optical measuring methods to determine foam characteristics such as foam volume, stability, drainage as well as foam structure.

The SITA FoamTester offers:

| • | Fast contact-free and high-resolution optical scan of the foam surface with structured light |

| • | Reliable and continuous detection of the foam-liquid interface even with opaque liquids |

| • | Fast and high-resolution measurement of the foam structure for the entire foam level, analysis of the different bubble sizes and other characteristic values |

| • | Fully-automated measuring process including sample conditioning and cleaning |

| • | Reproducible foam generation with reliable SITA stirring method and flexible test parameters |

| • | Individually programmable sequences for generating and analysing foam as well as easy operation with pre-set or costumised experiments |

The foam testing system consists of a removable measuring vessel with stirring unit, an integrated sample reservoir with magnetic stirrer, a cleaning system with external water source, an automatic optical measuring system and a touch display for operation directly at the device as well as the software SITA-FoamLab.

Applications

| • | Cosmetics |

| • | Cleaning agents / chemistry |

| • | Inks |

| • | Paints and coatings |

| • | Cooling lubricants |

| • | Pharmacy |

| • | Plastics manufacturing |

| • | Paper manufacturing |

| • | Textile chemistry |

| • | Beverage production |

| • | Wetting agents / electroplating |

Technical Data

| Foaming of the sample | |

| Recommended sample volume | 200 … 500 ml |

| Usable measuring vessel volume | 1,500 ml (incl. foam) |

| Capacity of storage vessel | 2,000 ml |

| Sample tempering of measuring and storage vessel | 0 … 60 °C with optional thermostat |

| Stirring speed | 0 … 2,000 U/min (bidirectional) |

| Adjustable stirring programs | Speed, duration, direction, acceleration |

| Analysis of foam structure |

|

| Evaluation area | height 130 mm width 50 mm |

| Resolution | 3,200 dpi |

| Results | bubble number and size distribution, other characteristic values |

| in standard measuring vessel with SITA-FoamLab Expert | |

| Measurment of foam volume |

|

| Foam volume | 0 … 1,500 ml; resolution 1 ml |

| Liquid volume & drainage | 0 … 500 ml; resolution 1 ml |

| General data | |

| Rinse connection | 3/4“ 2 … 6 bar |

| Power supply | 100 … 240 V / 50 … 60 Hz, 300 W |

| Dimensions (HxWxD) | 770 x 450 x 305 mm |

| Weight | ca. 35 kg |

Available Models

| SITA Foam Testing System Expert | |

| Consisting of | |

| • |

SITA FoamTester

for analysis of the foam characteristics foam volume, foam stability, drainage and foam structure |

| • | Software SITA-FoamLab Expert incl. the module for foam structure analysis |

| SITA Foam Testing System Basic | |

| Consisting of | |

| • | SITA FoamTester for analysis of the foam characteristics foam volume, foam stability, drainage |

| • | Software SITA-FoamLab Basic |