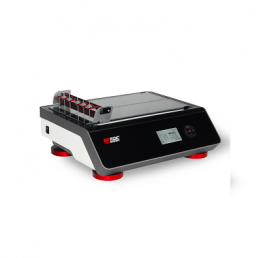

The BK 3 Speed Drying Recorder has been used widely in the coatings industry throughout the world for several decades. A needle carrier holding six hemispherical ended needles travels the length of the six 305 x 25 mm test strips in 6, 12 or 24 hours. Other speeds are available to special order. A time scale on the side cover is graduated to suit the three different travel times.

The BK 6 and BK 10 Recorders have independently operating tracks allowing tests to be made at different start times. Pairs of tracks operate at the same speed, and a wide range of travel times are available. Travel times of 6, 12, 24 and 48 hours are all considered as standard. A time scale on the front cover is graduated to suit the instrument’s drying time ranges. Each pair of tracks has its own individual operating switch.

|

Stages in the Drying Process Defined as:

|

|

- The first stage is a pear-shaped impression corresponding to the time taken for evaporation of solvent.

- The second stage is the cutting of a continuous track, corresponding to a sol-gel transition.

- The third stage is an interrupted track corresponding to the surface-dry time.

- A fourth stage is where the needle no longer penetrates the film, corresponding to the final drying time.

|

|

A typical white enamel would have a drying time expressed as follows: 1-1/4 —-3-1/2—-4 (hours)

Although all stages recorded are significant it is often sufficient to express a drying time in terms of set-time and hard-dry time, thus: 1-1/4 – 4 (hours). Brass weights, each weighing 5 g, may be used to apply greater pressure on the needles and thus record the through-drying properties of alkyds, varnishes and paints. The 3-SPEED BK DRYING RECORDER will give useful information about the gelation times of many two component surface coating materials and about the properties of such films. |

|

Method of Use

|

|

- Select the required speed by turning the speed control knob in a clockwise direction and sliding in or pulling out to the required speed. Release knob.

- Apply film to the test strips and place them on the Recorder.

- Lift the release lever on the back of the needle carrier and slide it to the starting position.

- Lower the needles on to the test strips.

- Switch on and the needles will now commence the run along the strips. On reaching the end of the travel, the carrier automatically stops. Switch off.

- Individual glass strips may be removed from the machine simply by depressing one end at the strip so

- that the opposite end tilts clear at the holder.

|

|

Determination of Drying Time

|

|

| The drying time of alkyds, varnishes or paints is determined by adding the requisite drier and thinning to a viscosity at which the material is normally applied. The finish is allowed to stand at room temperature for 24 hours to “mature”. A test strip measuring 12″ x 1″ (which may be of plain or ground glass or of other suitable material) is prepared by casting a film upon it by means of a special applicator which is accurately ground at one end to deposit a wet film thickness of 1.5 mils and 3 mils at the other. The test strips are placed on the table in their holders and the instrument is then operated as indicated below. |

|