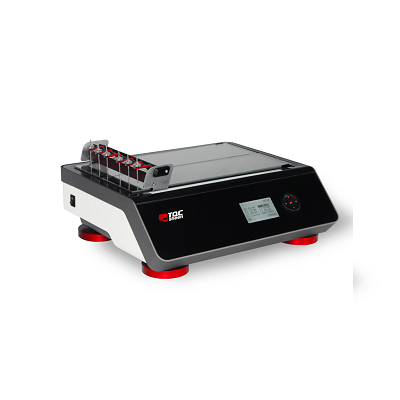

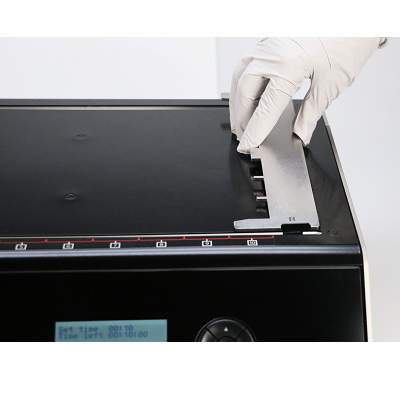

The Drying Time Recorder is a fully digitally controlled machine to define the different stages in the drying process of paints and coatings. The Drying Time Recorder operates conform the BK (Beck Koller) method. Defining the final result or checking intermediate stages is very easy by means of the clear digital display and the intuitive interface. The compact machine meets ASTM D5895, ISO 9117-4 and DIN EN 14022. The Drying Time Recorder has six tracks, and comes with two robust and reusable glass beds of 100 X 350 X 3 mm. Optional are six narrow glass beds in special adapters.

The front panel of the Drying Time Recorder is made out of clear glass, which is easy to clean and protects the display underneath it. The Drying Time Recorder is powered by a safe 24 V DC power supply.

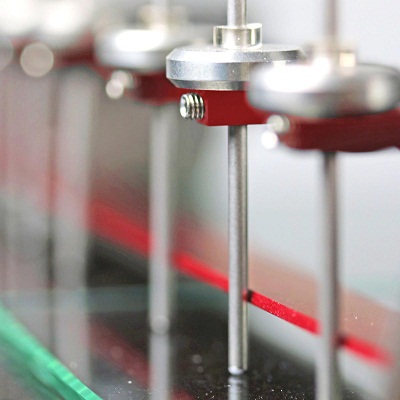

Temperature-friendly Design

The possibility to perform tests at temperatures as low as -20 °C is unique. The drive system is lubricant free, so there is no risk of lubricants that thicken at lower temperatures. The display is heated which enhances menu visibility at lower temperatures. These design features result in a wide operating temperature range from -20°C to +70°C (non-condensing), which makes it possible to perform tests in climate chambers.

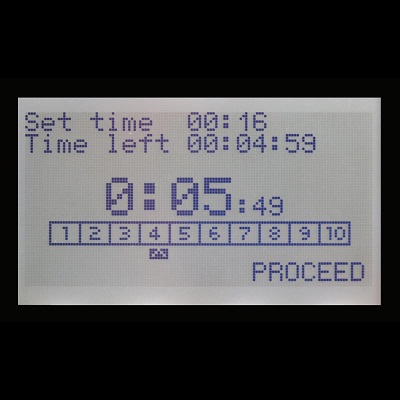

Broad and flexible time range

A broad and flexible time range can be set varying from 1 minute up to 200 hours. This makes the Drying Time Recorder suitable for fast drying waterborne coatings as well as very slow drying paints that may need days to dry. Time settings are very accurate, < 1 % of set time.