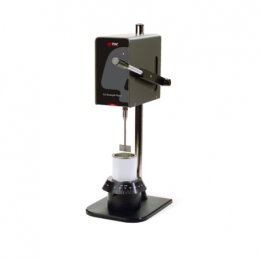

The DVPlus Viscometer is AMETEK Brookfield’s latest entry-level viscometer with an advanced user interface and best-in-class features. Our newest model is suitable for all applications where accurate viscosity measurements are needed. The easy-to-use, stand-alone interface makes DVPlus the perfect Viscometer for busy labs.

With the DVPlus Viscometer, you get it all: high accuracy, fast response time, and repeatable results.

NIST-traceable viscosity standards are available.

FEATURES & BENEFITS

- 5-inch full-color touch screen display with a dynamic user interface for direct access to the features

- Advanced interface with enhanced controls and a real-time test indicator

- Displayed info includes Viscosity (cP, mPa∙s, P, Pa∙s), Temperature (°C, °F or K), Torque (%, mNm, Dyne∙cm), Speed/Spindle, and Step Program Status

- USB and Bluetooth* interface for use with the DVPlus Connect app

- Temperature offset capability to ±5°C

- Choice of multiple languages, including English, French, German, Portuguese, Chinese, Japanese, and Spanish

- Total of 740 speeds for an excellent range capacity

- Optional RTD Temperature Probe (DVP-94Y)

- Direct access to the time measurement function (time to torque, time to temperature, time to stop).

- Automatic range calculation:

- Full-Scale Range (FSR) at 100%

- Maximum Viscosity measured with Spindle / Speed Combination

- Accuracy of ±1.0% of range

- Repeatability of ±0.2%

- 17025 Calibration (Optional)

Each of our standard Viscometers is supplied with an internal spring used to calculate the viscosity of a material. These springs have different measuring capabilities:

LV is for low viscosity materials and can measure the thinnest materials. Typical examples include inks, oils, and solvents.

RV is for medium viscosity materials than those measured with an LV torque. Typical examples include creams, food, and paints.

HA is for higher viscosity materials than those measured with an RV torque. Typical examples include gels, chocolate and epoxies.

HB is for even higher viscosity materials than those measured with an HA torque spring. Typical examples include asphalt, caulking compounds, and molasses.

Note: Additional special springs are also available upon request.