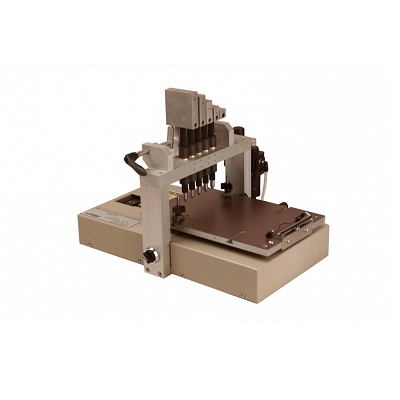

The Multi-Finger Scratch / Mar Tester includes a pneumatically driven, moveable platform to which the test specimen is mounted. The platform moves in a linear fashion, and is operated by a control knob for single or multiple pass testing. An electronic timer displays the rate of speed, which can be controlled by reducing or increasing air pressure.

A gantry supports five independent splined-fingers, which provide a constant, vertical load on interchangeable scratch tips. The gantry system includes a handle to raise and lower the arms. In addition, five support rests are incorporated to allow one or more arms to be moved to an upright, rest position such that the arm does not contact the specimen during testing.

Individual weights of varying loads mount to the top of each arm finger to exert a standard force on the surface of the test material. Each instrument includes a weight set of 2N, 3N, 4N, 5N, 6N, 7N, 10N, 15N and 20N loads. Optional weights sets are also available consisting of either 4N, 8N, 9N, 12N or 8N, 13N, 18N weights. In addition, an optional weight of 25N or Precision Weight Kit to achieve 0.6N loads are available.

Although flat specimens up to 22mm thick are normally tested, the ‘free-floating’ arms fingers enable you test slightly contoured specimens provided they are rigid or adequately supported. A spring-loaded specimen holder is standard and can be mounted to the end or side of the moveable platform for greater flexibility. To mount contoured specimens, two specimen hold-down clamps are provided. An optional 5mm spacer set is available to raise the gantry to accommodate specimens that are greater than 22mm thick.Each Multi-Finger Scratch / Mar Tester includes a set of five 1.0mm diameter hemisphere Scratch Tips and 7.0mm diameter hemisphere Mar Tips. Both include a precision tungsten carbide ball mounted to the contact end. Optional conical scratch tips are also available in either tungsten carbide (0.1mm; 0.25mm; 0.4mm and 0.5mm diameter) or diamond (with 90° 3mil or 90° 3.5mil radius point).

Depending on the type of material under evaluation, the visual appearance of a scratch normally involves changes in surface topography, color, or brightness. Three methods are normally used:

Visual Evaluation – For this technique, the observer uses a controlled light source to visually inspect each scratch line and rates according to a Rating Scale 1 to 5 (1 = no scratch line at all; 5 = severe scratch line). For plastic materials, indicate if the line exhibits signs of whitening.

Width/Depth – Using an optical measuring device such as an Optical Micrometer, the operator measures the width and / or depth of the scratch.

Image Analysis – Another option would be to use an Image Analysis technique such as SEM.

Detailed descriptions are recommended when depicting scratch or mar damage. Items that might be described include surface topography, material deformation, material removal, and color changes. The following examples have been used to describe damage in plastics:

-

scratch is shallow (or deep)

-

scratch is smooth, with a well defined shape (or rough and deformed)

-

scratch includes plastic flow of the material (or cutting, tearing, cracking, chipping, crazing)

-

scratch includes visible ripple marks at the bottom (i.e. chevron or parabolic shaped)

-

strain whitening is visible (or no change in color)