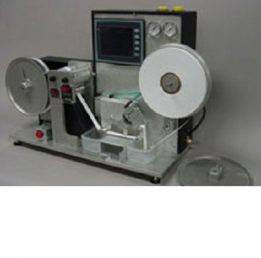

The TABER® Rotary Platform Abrasion Tester – Model 1700 / 1750 is commonly referred to as the Taber Abraser (Abrader) or Rotary Platform Dual (Double) Head Tester. First introduced in the 1930’s, this precision built instrument was developed to perform accelerated wear testing. Capable of providing reliable data in a matter of minutes compared to the years that may be required by in-use testing, the Taber Abraser (Abrader) rapidly became the world standard for evaluating abrasion resistance.

Since its inception, the Taber Abraser has been used for quality & process control, research & development and material evaluation. Used to test a wide spectrum of materials, the instrument has been referenced in numerous standards and specifications (including plastics, coatings, laminates, leather, paper, ceramics, carpeting, safety glazing, etc.).

Taber tests involve mounting a flat specimen approximately 100mm square or round to a turntable platform that rotates on a vertical axis at a fixed speed. The standard material thickness that can be evaluated with the Taber Rotary Abraser is 6.35 mm (materials greater than 6.35 mm but less than 40 mm can be tested with optional accessories). Two genuine Taber abrasive wheels, which are applied at a specific pressure, are lowered onto the specimen surface.

Characteristic rub-wear action is produced by contact of the test specimen against the sliding rotation of the two abrading wheels. As the turntable rotates, the wheels are driven by the sample in opposite directions about a horizontal axis displaced tangentially from the axis of the sample. One abrading wheel rubs the specimen outward toward the periphery and the other, inward toward the center while a vacuum system removes loose debris during the test. The wheels traverse a complete circle on the specimen surface, revealing abrasion resistance at all angles relative to the weave or grain of the material. The resulting abrasion marks form a pattern of crossed arcs in a circular band that cover an area approximately 30 cm2.

Each turntable has dual abrading arms that are precision balanced. Independently operated, the abrading arms can be raised (or lowered) to mount or inspect specimens. Each arm is precision balanced and will apply a load of 250 grams against the specimen, exclusive of the weight of the wheel. To increase the load to 500 or 1000 grams, a mount for auxiliary weights is located on the outside of the abrading wheel bearing assembly. This location ensures that weights are concentric with the abrading wheel. A stud on the rear end of the abrading arm is used to carry an optional counterweight (used to reduce the load by 50, 125, 150 or 175 grams).

Taber Abraser Model 1700 or 1750 offer the following standard features:

-

Specimen turntable speed control allows options of both 60 rpm and 72 rpm.

-

Easy-to-use LCD operator touch screen interface with selectable display options (including language selection).

-

A vacuum system is included and is critical for the proper operation of the instrument. The direct flow vacuum nozzle is hinged to an adjustable mount at the rear of the housing. The nozzle includes two 8mm diameter orifice screw-in nozzle tips (11mm are sold separately). A precision vacuum nozzle adjustment control allows the height to be modified for accommodating varying specimen thickness.

-

Compact abraser arm assemblies provide a standard load of 250 gram on the wheel. Using the auxiliary weights, standard wheel loads of 500 or 1000 grams can be obtained. Please note, the markings on the auxiliary weights are NOT reflective of the actual mass of the additional weight. The auxiliary weights are marked with the TOTAL load that will be exerted on the wheel and equals the combined mass of the abraser arm and auxiliary weights. The weight marked 500 gram is actually 250 grams and the weight marked 1000 gram is actually 750 grams.

-

A Quick Release Mounting Hub permits quick wheel mounting without the need of a locking nut, resulting in increased clearance for the vacuum pick-up nozzle and a larger viewing area for the test specimen. A spring loaded, beveled retaining nut provides a positive locking force on the wheel hub retaining lip making certain that the wheels remain securely fastened until disengaged.

-

Each specimen table includes an independent support frame to which the abraser arm and nozzle assemblies are affixed.